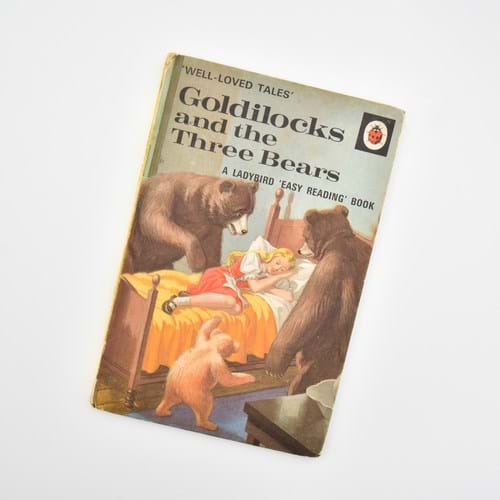

Creating products to Goldilocks’ standard (Day 342)

4th May 2015

This is the aim of chemical engineers who work on the development and delivery of consumer products. There is a strong focus on achieving a consistent outcome that the customer deems to be ‘just right’.

I recently attended a talk given by Professor David York, Chair of Structured Particulate Products, from the University of Leeds, UK, on how to convert commodities into high value components.

David described how science and engineering are applied to transform household detergents into higher value specialty products. He went on to explain how improved consumer satisfaction is being delivered by creating a washing product that leaves an appealing fragrance on freshly laundered clothes.

David and his team achieved this by creating a product that deposits perfume micro-capsules onto fabric during the wash cycle. The capsules subsequently fracture and release a pleasing odour in controlled doses.

However, for this type of development to make it to the production line, the process must be robust, reliable and deliver a cost-effective finished product with the right functionality.

This was achieved through the adoption of a manufacturing strategy that borrowed an approach from elsewhere, using product design from a different consumer good - in this instance, business stationery.

The breakthrough came when David and his team took a look at the technique used to manufacture carbonless copy paper, a type of paper designed to transfer information written on a top sheet to one underneath it without the need to use a carbon paper insert. Carbonless copy paper contains ink micro-capules on the reverse side of the paper that rupture on impact during typing. Its use has declined since the 1990s following the advent of the ink jet printer. The team discovered that the process used to produce micro-capsules containing ink, could be adapted to manufacture perfume capsules.

Using the Goldilocks strategy of developing a product that was ‘just right’, David searched for appropriate measurement techniques that would allow him to develop an odour that was not too weak and not too strong.

He achieved this using micromanipulation techniques developed by Professor Zhibing Zhang from the University of Birmingham, UK, to formulate perfume capsules with the desired strength and a shelf-life of at least 12 months.

David applied the priniciples described by Fick’s law of diffusion to establish a simple, fast test to optimise the thickness of the perfume capsule membrane in the final product formulation. Thicker membranes reduce leakage and improve shelf-life, but David's team also wanted to get the delivery of the perfume just right.

David's discovery turned around the fortunes of a company that was making a product - ink micro-capsules - for a market in decline. The company now makes a speciality product – perfume capsules - for detergents. The research has also been applied to other highly profitable branded products, showing that David got it ‘just right’.

David contends that academic research “Can transform traditional industries into high value ones”. I have to agree; not only has this research created profitable products, it has also spurred growth in academic research.

David and his team are now working to optimise the dimensions of the capsules; as bigger is best for shelf-life, but smaller is better for the release of odour.

The work at the University of Leeds, UK, provides a good illustration of the way in which chemical engineering can add value to established process technologies. Goldilocks would be delighted!

If you are working to upgrade existing consumer products, why not get in touch and tell us about it.